| Availability: | |

|---|---|

| Quantity: | |

We focus on the stamping forming bending welding part for engine oil pan, transmission oil filter, transmission oil pan, oil dipstick ,oil pickup tube strainer,auto coolant pipe ,bypass water pipe ,engine cylinder inlet water pipe ,thermostat cover ,thermostat connector pipe almost 30 years.

Founded in 1992, Started exporting in 2008, which is now covered more than 10000 square meters and with 439 employee.

31390-80X0A

Transmission oil pan reverse engineer

Got the outside profile of the oil pan by scanning .

Stamping press workshop

The most popular engine oil pan was produce by the stamping drawing ,we had about 30 set of stamping press cover from 30T to 2100T,those hydraulic pressure stamping machine can made the engine oil pan for auto to heavy duty truck engine oil sump from front oil sump to rear oil sump,the baffle and the other engine part bracket also produce in this workshop.

Stamping Workshop

Overview of the Stamping workshop with cover the

Stamping equipment from 100T to 800T.

Hydraulic Press cover from 50T to 3100T.

With the mold(die,tooling) produce by ourselves we can customize all kinds of metal shape according to customer drawing call out.

Stamping press deep drawing production process after the raw material blanking .

The shape of the oil pan start from this production process.

3D laser cutting production process ,when we develop a new project for a stamping part ,to short the lead time we will use the laser cutting production process instead of the stamping mold to take off the raw material as the drawing call out .the most beneficial for the 3D laser cutting machine was short the leadtime for the development.

09G transmission oil pan development process

To development the pan we need the drawing or sample .let`s start with the reverse engine project for the 09g transmission oil pan

1.We will scanning the sample of 09g transmission pan .

2.Read the data from the sample and create the 3D drawing .

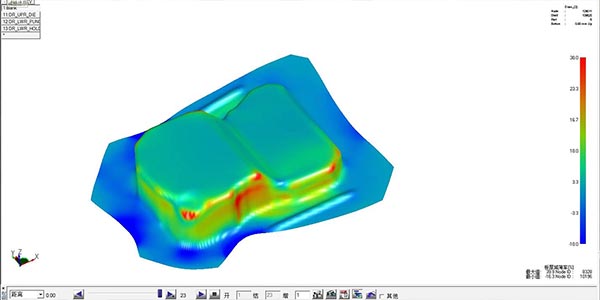

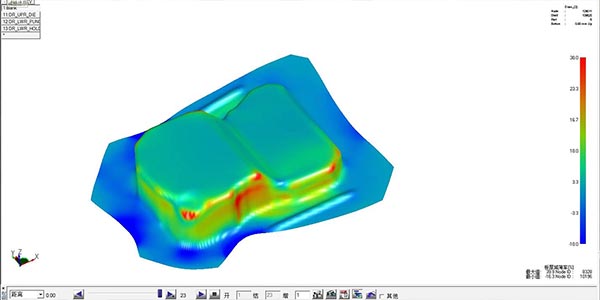

3.Simulation of the stamping production process .

4.Get to know where the 09g transmission oil sump easy to break or wrink.

The drawing press mold create by solidwork and simulation stamping by the J STAMPING software or CAE.

Stamping process for the 09g pan ,

Normally stamping process start from decoiling ,shear the steel plate sheet from the coil steel packing

Then stamping press the steel plate to form the shape as we need.

Engine oil pan leaking test

The engine oil sump was made by the steel plate sheet ,it maybe broken during the metal stamping drawing production process ,so each pan need to go though the leaking test before paint and ship

We focus on the stamping forming bending welding part for engine oil pan, transmission oil filter, transmission oil pan, oil dipstick ,oil pickup tube strainer,auto coolant pipe ,bypass water pipe ,engine cylinder inlet water pipe ,thermostat cover ,thermostat connector pipe almost 30 years.

Founded in 1992, Started exporting in 2008, which is now covered more than 10000 square meters and with 439 employee.

31390-80X0A

Transmission oil pan reverse engineer

Got the outside profile of the oil pan by scanning .

Stamping press workshop

The most popular engine oil pan was produce by the stamping drawing ,we had about 30 set of stamping press cover from 30T to 2100T,those hydraulic pressure stamping machine can made the engine oil pan for auto to heavy duty truck engine oil sump from front oil sump to rear oil sump,the baffle and the other engine part bracket also produce in this workshop.

Stamping Workshop

Overview of the Stamping workshop with cover the

Stamping equipment from 100T to 800T.

Hydraulic Press cover from 50T to 3100T.

With the mold(die,tooling) produce by ourselves we can customize all kinds of metal shape according to customer drawing call out.

Stamping press deep drawing production process after the raw material blanking .

The shape of the oil pan start from this production process.

3D laser cutting production process ,when we develop a new project for a stamping part ,to short the lead time we will use the laser cutting production process instead of the stamping mold to take off the raw material as the drawing call out .the most beneficial for the 3D laser cutting machine was short the leadtime for the development.

09G transmission oil pan development process

To development the pan we need the drawing or sample .let`s start with the reverse engine project for the 09g transmission oil pan

1.We will scanning the sample of 09g transmission pan .

2.Read the data from the sample and create the 3D drawing .

3.Simulation of the stamping production process .

4.Get to know where the 09g transmission oil sump easy to break or wrink.

The drawing press mold create by solidwork and simulation stamping by the J STAMPING software or CAE.

Stamping process for the 09g pan ,

Normally stamping process start from decoiling ,shear the steel plate sheet from the coil steel packing

Then stamping press the steel plate to form the shape as we need.

Engine oil pan leaking test

The engine oil sump was made by the steel plate sheet ,it maybe broken during the metal stamping drawing production process ,so each pan need to go though the leaking test before paint and ship

content is empty!