Production workshop on site

12102-bz010-001 engine oil pan workshop on site

The steel pan from the sheet plate to drawing production process.

Shear the oil pan

The oil pan or sump , is a metal sheet part install at the bottom of the engine block, and storge engine lubricants oil for engine.

The oil pick up tube stay inside engine lubrication oil and suck up the oil and go though the engine by the oil pump.

The oil pan also play a key role in the coolant ,by the wind go around the pan and take the heat away.

Baffles

Oil sitting in the pan will slosh around as the car accelerates or break. oil can move away from the pickup pipe and cause oil to temporarily stop flowing through the engine. That was why the pan always need a baffles,Baffles can take various forms, but their purpose is to impede the flow of a huge body of liquid, while allowing ready flow of smaller amounts.

Drain plug

As the lowest point of the lubrication system, the sump is where the oil drain plug is located. Oil plugs are threaded bolts which are removed to allow dirty oil to drain. The drain plug will have a washer - which should ideally be replaced whenever it is removed. Oil is more easily drained when warm.

Dipstick

Engines use a dipstick as a means of determining the amount of oil in the engine. The dipstick will dip down into the oil pan and be marked to show the level of oil - with minimum and maximum markings. Recent cars will include an electronic oil level sensor which shows the oil level on a dashboard indicator.

09G transmission oil pan development process

To development the pan we need the drawing or sample .let`s start with the reverse engine project for the 09g transmission oil pan

1.We will scanning the sample of 09g transmission pan .

2.Read the data from the sample and create the 3D drawing .

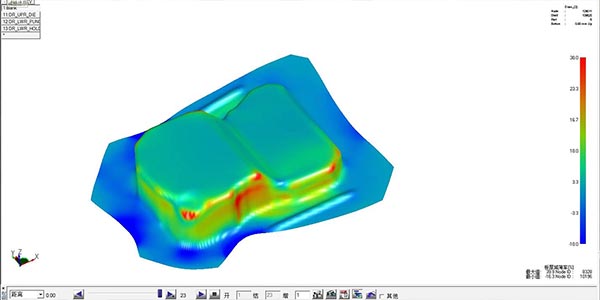

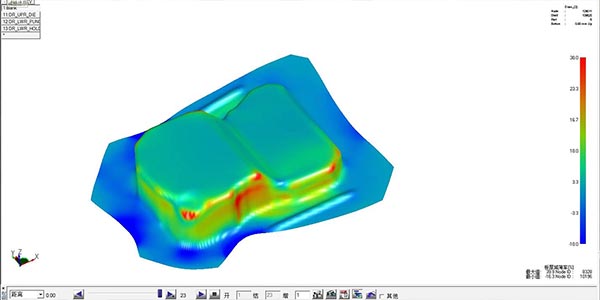

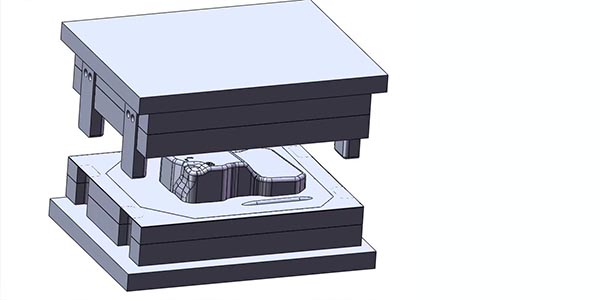

3.Simulation of the stamping production process .

4.Get to know where the 09g transmission oil sump easy to break or wrink.

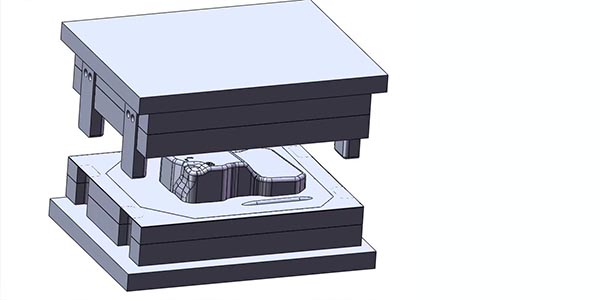

The drawing press mold create by solidwork and simulation stamping by the J STAMPING software or CAE.

Stamping process for the 09g pan ,

Normally stamping process start from decoiling ,shear the steel plate sheet from the coil steel packing

Then stamping press the steel plate to form the shape as we need.

1.What was the steel oil sump function in transmission

2.Oil pan production steel sheet preparation

3.Raw material Chemical element and mechanical property test

4.Steel oil sump deep drawing production process

5.Transmission shield welding for the oil package

6.OIl sump oil plug seat welding

7.Leaking test for the engine oil sump

1.Heavy duty engine oil pan sump development production process

Engine oil pan play a key role on lubrication system,All the lubrication for engine start from the pan ,the oil pump drive by the belt and pickup the oil from the engine oil sump by the oil pickup tube screen and oil pump

The first thing to give out the performance engine oil sump was the mold,due to most of the oil sump was made by the steel pan ,it was start by a steel sheet.

2.All the steel oil sump was starting by a steel decoiling process:

Decoiling raw materil

All the raw material from the steel factory was by the coil ,it was much more convenience to transport.

It was very friend for the storage,when we want to use those raw materil we need to break it into the steel sheet plate as our work instruction require.

The capacity for decoiling machine was:2500mm with 45T for a single coil.

3.Raw material Chemical element and mechanical property test

Chemical element and mechanical property test

All the raw material need to go though Chemical element and mechanical property test before go into the mass production workshop.

If the Elongation rate was too low it cant be use for engine oil pan production due to the deep drawing production process.

We need to know the batch of raw material yield strength and tensile strength so that the press can give out the proper force to drawing and forming the engine oil sump

4.steel oil sump deep drawing production process

Steel pan drawing process

When we get the steel sheet plate from the decoiling ,the next production was the deep drawing stamping production process.

We give the press force for hydraulic pressure as result from Chemical element and mechanical property test

The first piece of the steel oil pan oil sump need to go though by the dimension inspection according to the quality control system.if the dimension meet the drawing requirement ,then we move into mass production.

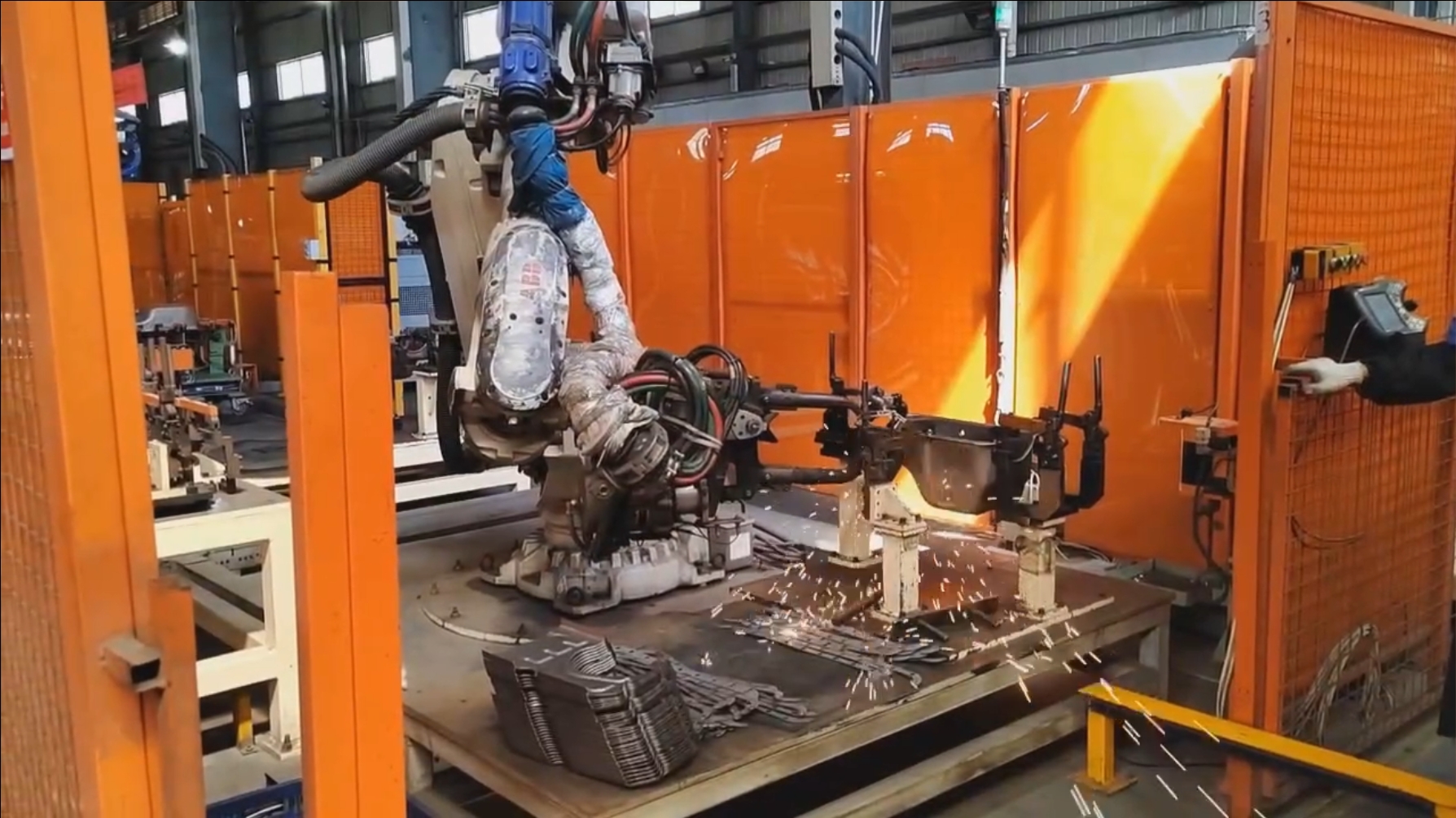

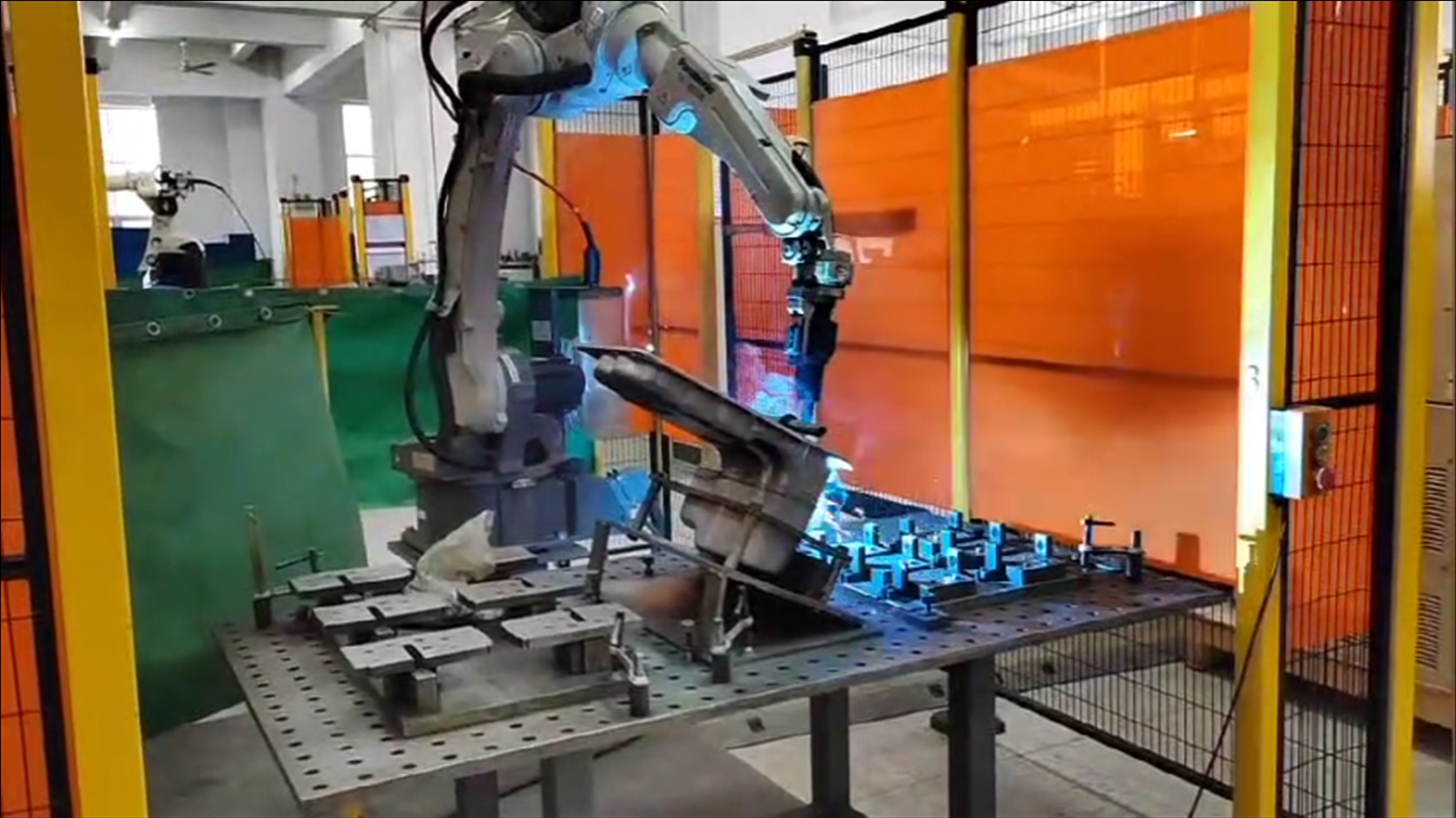

5.Transmission shield welding for the oil package

Shield welding for oil sump

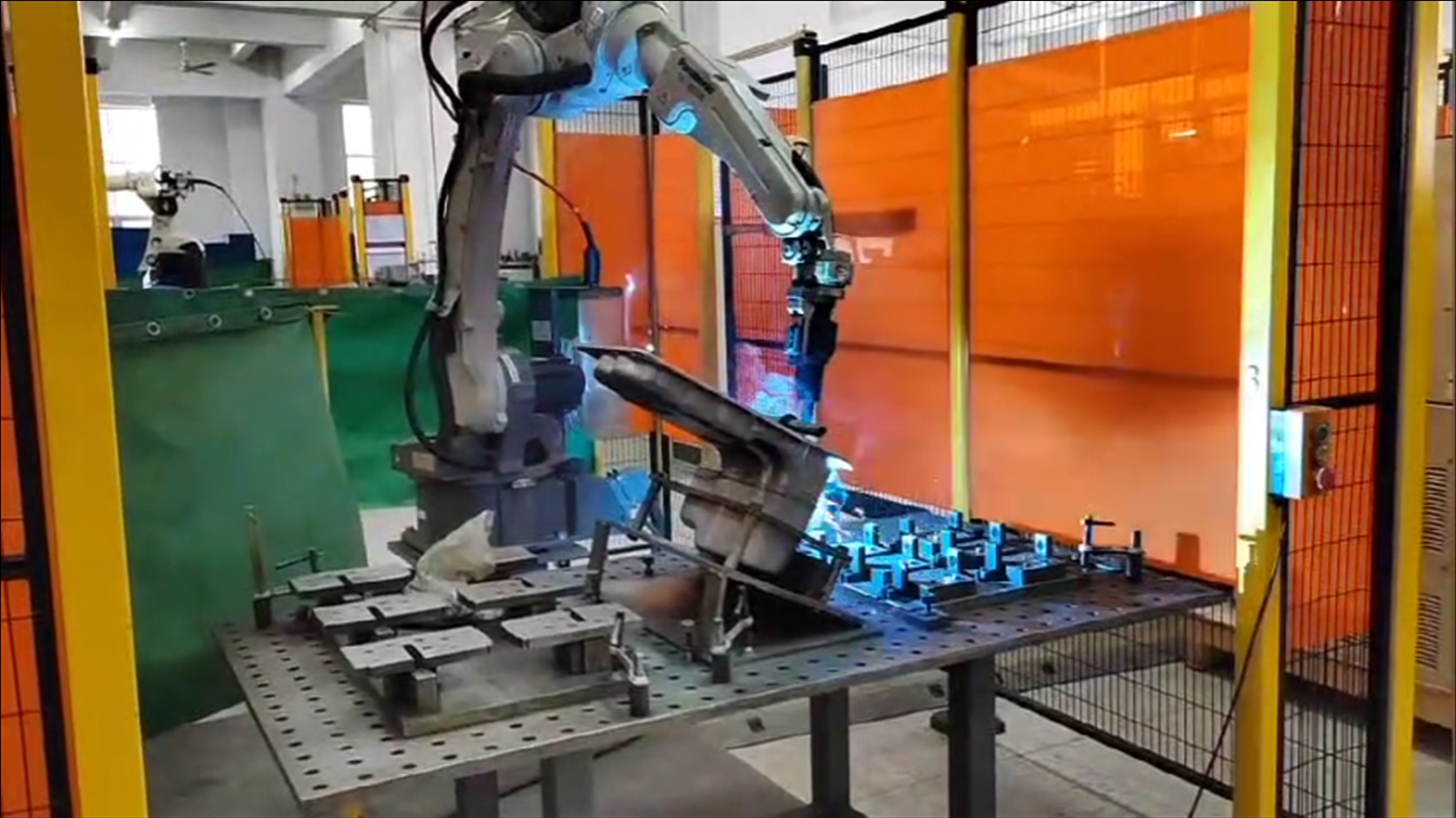

When the OEM design the car there was some space limit ,so the pan cant be stamping drawing by just one production process ,we need to weld two stamping part of the pan together.That was why we need MIG welding

We use the robot to control welding parameter such as Current, voltage, gas flow rate

The capacity for the robot was 1800mm*1000mm*800mm carry the most current for welding machine was 500A

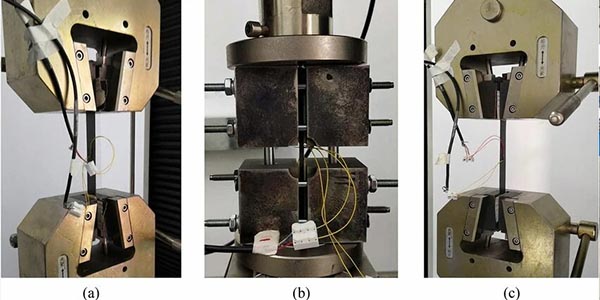

6.OIl sump oil plug seat welding

OIl sump oil plug seat welding

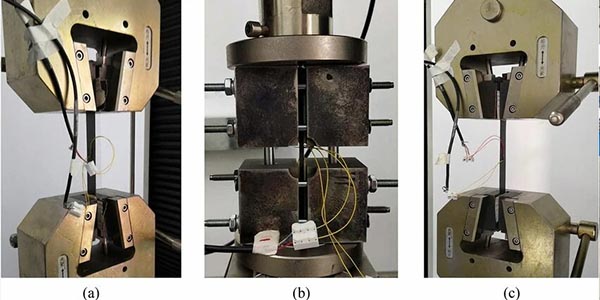

The oil plug for the pan was another work piece which need to be welding on the oil pan by spot welding.

To increase the production capacity we will the ABB robot insted of human laobr spot welding.

We need to Knockout test the sample before mass production according to the quality control system.

7.Leaking test for the engine oil sump

Leaking test for the engine oil sump

There may be Burn through case during the welding process ,so each pan need to go though by the leaking test

By immerse the whole pan into water by a special equipment and 10bar air push inside the pan ,after 30 second if there was leak bubble around all the pan ,the pan was ok ,otherwise the pan will be reworking .

We were the auto part metal stamping bending pressing forming bending company for metal part almost 30 years .

Our main production :Engine oil pan, oil sump, transmission oil pan, oil sump, engine oil pick up, engine oil filter, transmission oil filter, oil dipstick, auto coolant pipe

Production workshop on site

12102-bz010-001 engine oil pan workshop on site

The steel pan from the sheet plate to drawing production process.

Shear the oil pan

The oil pan or sump , is a metal sheet part install at the bottom of the engine block, and storge engine lubricants oil for engine.

The oil pick up tube stay inside engine lubrication oil and suck up the oil and go though the engine by the oil pump.

The oil pan also play a key role in the coolant ,by the wind go around the pan and take the heat away.

Baffles

Oil sitting in the pan will slosh around as the car accelerates or break. oil can move away from the pickup pipe and cause oil to temporarily stop flowing through the engine. That was why the pan always need a baffles,Baffles can take various forms, but their purpose is to impede the flow of a huge body of liquid, while allowing ready flow of smaller amounts.

Drain plug

As the lowest point of the lubrication system, the sump is where the oil drain plug is located. Oil plugs are threaded bolts which are removed to allow dirty oil to drain. The drain plug will have a washer - which should ideally be replaced whenever it is removed. Oil is more easily drained when warm.

Dipstick

Engines use a dipstick as a means of determining the amount of oil in the engine. The dipstick will dip down into the oil pan and be marked to show the level of oil - with minimum and maximum markings. Recent cars will include an electronic oil level sensor which shows the oil level on a dashboard indicator.

09G transmission oil pan development process

To development the pan we need the drawing or sample .let`s start with the reverse engine project for the 09g transmission oil pan

1.We will scanning the sample of 09g transmission pan .

2.Read the data from the sample and create the 3D drawing .

3.Simulation of the stamping production process .

4.Get to know where the 09g transmission oil sump easy to break or wrink.

The drawing press mold create by solidwork and simulation stamping by the J STAMPING software or CAE.

Stamping process for the 09g pan ,

Normally stamping process start from decoiling ,shear the steel plate sheet from the coil steel packing

Then stamping press the steel plate to form the shape as we need.

1.What was the steel oil sump function in transmission

2.Oil pan production steel sheet preparation

3.Raw material Chemical element and mechanical property test

4.Steel oil sump deep drawing production process

5.Transmission shield welding for the oil package

6.OIl sump oil plug seat welding

7.Leaking test for the engine oil sump

1.Heavy duty engine oil pan sump development production process

Engine oil pan play a key role on lubrication system,All the lubrication for engine start from the pan ,the oil pump drive by the belt and pickup the oil from the engine oil sump by the oil pickup tube screen and oil pump

The first thing to give out the performance engine oil sump was the mold,due to most of the oil sump was made by the steel pan ,it was start by a steel sheet.

2.All the steel oil sump was starting by a steel decoiling process:

Decoiling raw materil

All the raw material from the steel factory was by the coil ,it was much more convenience to transport.

It was very friend for the storage,when we want to use those raw materil we need to break it into the steel sheet plate as our work instruction require.

The capacity for decoiling machine was:2500mm with 45T for a single coil.

3.Raw material Chemical element and mechanical property test

Chemical element and mechanical property test

All the raw material need to go though Chemical element and mechanical property test before go into the mass production workshop.

If the Elongation rate was too low it cant be use for engine oil pan production due to the deep drawing production process.

We need to know the batch of raw material yield strength and tensile strength so that the press can give out the proper force to drawing and forming the engine oil sump

4.steel oil sump deep drawing production process

Steel pan drawing process

When we get the steel sheet plate from the decoiling ,the next production was the deep drawing stamping production process.

We give the press force for hydraulic pressure as result from Chemical element and mechanical property test

The first piece of the steel oil pan oil sump need to go though by the dimension inspection according to the quality control system.if the dimension meet the drawing requirement ,then we move into mass production.

5.Transmission shield welding for the oil package

Shield welding for oil sump

When the OEM design the car there was some space limit ,so the pan cant be stamping drawing by just one production process ,we need to weld two stamping part of the pan together.That was why we need MIG welding

We use the robot to control welding parameter such as Current, voltage, gas flow rate

The capacity for the robot was 1800mm*1000mm*800mm carry the most current for welding machine was 500A

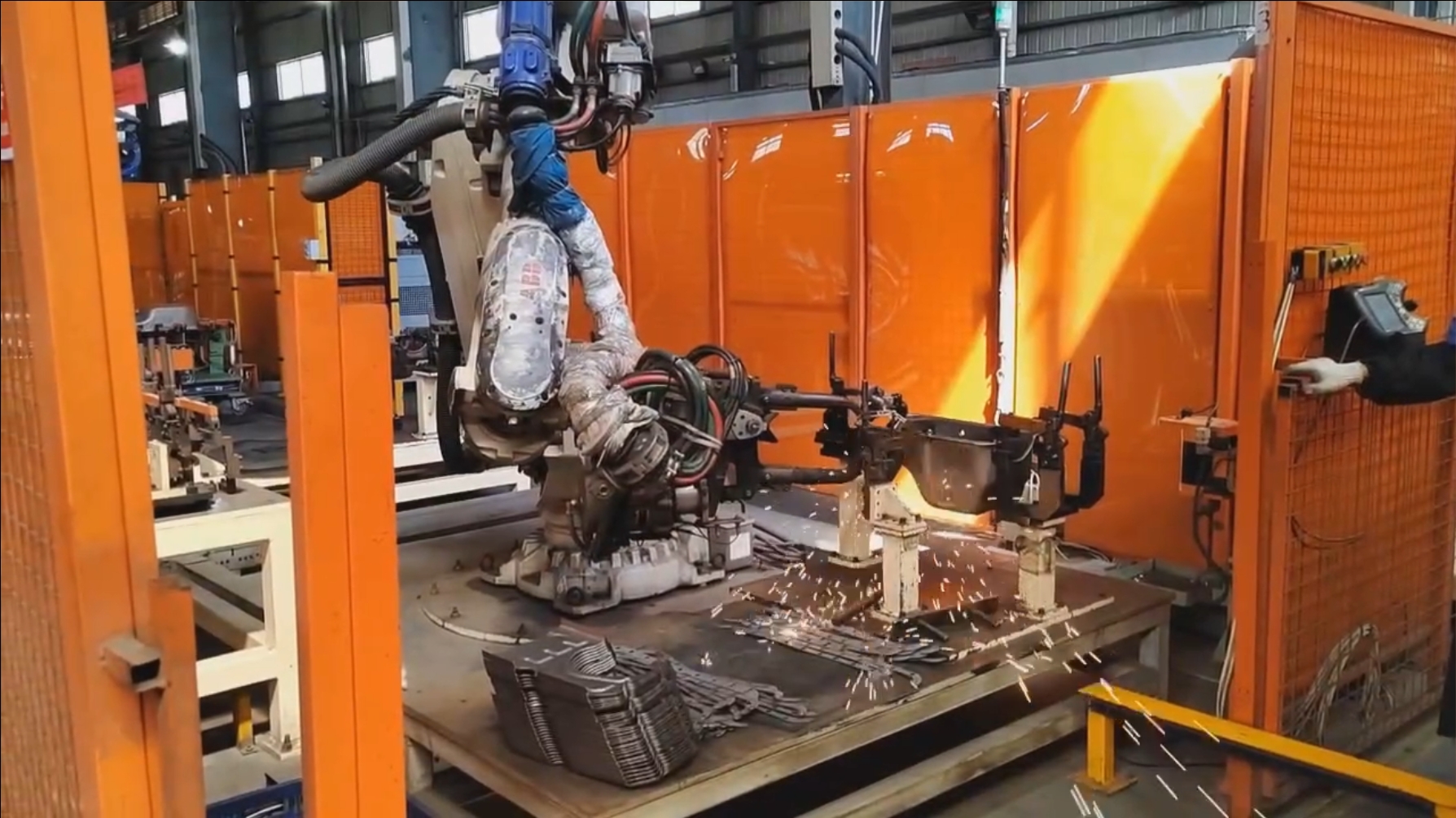

6.OIl sump oil plug seat welding

OIl sump oil plug seat welding

The oil plug for the pan was another work piece which need to be welding on the oil pan by spot welding.

To increase the production capacity we will the ABB robot insted of human laobr spot welding.

We need to Knockout test the sample before mass production according to the quality control system.

7.Leaking test for the engine oil sump

Leaking test for the engine oil sump

There may be Burn through case during the welding process ,so each pan need to go though by the leaking test

By immerse the whole pan into water by a special equipment and 10bar air push inside the pan ,after 30 second if there was leak bubble around all the pan ,the pan was ok ,otherwise the pan will be reworking .

We were the auto part metal stamping bending pressing forming bending company for metal part almost 30 years .

Our main production :Engine oil pan, oil sump, transmission oil pan, oil sump, engine oil pick up, engine oil filter, transmission oil filter, oil dipstick, auto coolant pipe